|

|||

| WJ-CEI Home Page | My Publications | Research Material Donations | Bio and Contact |

Communication Electronics, Inc |

Bethesda and Rockville, Maryland |

| CEI Main Page | CEI Receivers | CEI History | CEI Related History | CEI Documents |

| CEI-WJ receivers and tuner guide |

CEI-WJ surveillance system guide |

CEI-WJ spectrum display guide |

WJ- CEI Receivers |

CEI History |

| 1966 CEI catalog | 1968 CEI catalog |

The Gaithersburg facility of Watkins Johnson (WJ) started as an independent company, Communication Electronics, Inc (CEI). Communication Electronics, Inc. was founded in 1960 by a group of Vitro Electronics employees under the leadership of Ralph E. Grimm. Employees at Vitro Electronics had been growing dissatisfied with the New York based management of Vitro Laboratories. Vitro purchased the previously independent Nems-Clarke in 1957 and renamed it Vitro Electronics. Ralph Grimm, Ed Gearing, Peter Pao, Paul Maddox, Ken Shen and one or two others left Vitro Electronics. Using financing from the Baltimore based investment firm of Baker Watts (now Ferris Baker Watts), they started CEI. They moved into a space above and adjacent to Community Auto Service on the corner of Hampden Lane and Woodmont Avenue in Bethesda, MD. Community Auto Service is still in business as seen from this December, 2007 photo. This is the place where the development of modern surveillance radios and COMINT techniques began. |

|||||

|

|||||

CEI's manufacturing facility started on the second floor above the garage (on the left in picture) which is 4900 Hampden Lane. Engineering and sales were located up the hill in an annex (blue awning on far right) which is 4908 Hampden Lane. There is no internal route between the two parts. To go from engineering to manufacturing, a staff member had to walk outside, down the hill and then up the stairs to the other part of the building. Early manuals and sales literature use the two addresses in a seemingly random fashion. The business took off quickly. Their main competitor, Vitro Electronics, had previously lost several engineers to Defense Electronics, Inc (along with much of their telemetry receiver business). The engineering staff was further decimated by departures to CEI. In addition, Ralph Grimm had the connections to US intelligence agencies. The final piece of the puzzle was that Allen S. Clarke, who was the president of Nems-Clarke when Vitro purchased it, resigned from Vitro and joined the CEI board of directors. Thus CEI was able to quickly take over the market from Vitro Electronics. |

|||||

| The earliest equipment produced in the Bethesda facility on Hampden Lane bore either the red and black medallion pictured on the right or the silver logo and Bethesda, Maryland location silk screened on the front panel like the receiver pictured below. | |||||

|

|||||

The first CEI receiver was the 901 (pictured above). The RF tuners were designed by Peter Pao and the rest of the electronics were designed by Ralph Grimm. The mechanical design was done by Marcos Belen. The receiver is a standard rack mount package, 3-1/2" high, which is called "2U". It bears a strong resemblance to the Nems-Clarke 1906 , but is a clearly a new radio substituting nuvistors for the 7 & 9 pin tubes used in the 1906. The sheet metal, machined parts and printed circuit boards were all designed and produced on site. Every piece of CEI equipment had a thick milled aluminum front panel. A CEI engineer once suggested to Ralph Grimm that punched front panels would be cheaper. Ralph tersely informed him, "No CEI radio will ever have a punched panel." |

|||||

Even the transformers were designed by the staff and fabricated, potted and sealed in CEI's transformer shop. The photo at the right is the transformer shop at 4908 Hampden Lane. Ron Bobick is operating the coil winder in the foreground. The other staff are unknown. The large pressure vessel in the rear on the left was for impregnating the windings prior to potting them inside sealed metal cans. |

|

||||

|

In the early 1960s one of the plating tanks at Hampden Lane leaked and took the paint off the hoods of several cars downstairs. It was an expensive spill. At that time, Community Car Service specialized in Cadillacs and Buicks. |

||||

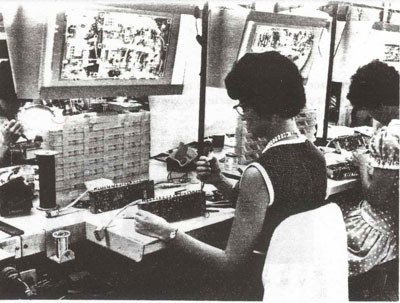

Ralph Grimm's high standards filtered right down to the assembly room floor. After a production design was finalized, he took careful pictures of the subassemblies and blew them up for display above each assembly station. This ensured every unit was built in the same manner. Component and lead placement is critical to quality control in the construction of VHF, UHF and microwave radios. The photo at the left is probably not staged. There was no written dress code, but sharp looking dresses, high heels and jewelry were everyday wear for the predominately female assemblers. Assembling CEI equipment was no ordinary job. |

|

||||

Ralph Grimm personally came down to the assembly area each Christmas to hand deliver bonus checks that in good years sometimes amounted to 2-3 weeks salary. He knew the contributions by the assemblers were as valuable to the success of CEI as any other employee. The performance, quality and reliability of CEI equipment was their major selling point. The customers, who were predominately from the intelligence community, needed the best radios money could buy. The equipment had to work as promised both when delivered and on demand. CEI radios met these criteria through elegant engineering and scrupulous attention to detail. CEI was famous for absolutely backing up their products. CEI grew very fast and the Hampden Lane facility was bursting at the seams within a few short years. CEI started renting space in a building across the street and relocated the mechanical engineers and the special products division. This sprawling enterprise needed a new home. |

|||||

|

Vince Noonan, the financial manager, obtained more financing from Baker Watts and CEI started construction of a new facility on Executive Boulevard in Rockville, Maryland. At that time, this area was on the north west edge of the expanding DC metro area. Executive Blvd. was a dead end, terminating in a cul-de-sac at the right edge of the color photo below. CEI moved into 6006 Executive Blvd. in 1964. The company had 43 employees. Bill Bruff, who was then a mechanical engineer, recalls the new place felt positively spacious, even though the building looks quite modest today. (It is presently an early education center.) |

||||

But CEI continued to grow at a frantic pace. These were the days of Soviet missiles being shipped into Cuba. The ominous echo of Premier Nikita Khrushchev's "We will bury you" still resonated across America. Demand for CEI products was understandably high. Eventually CEI had facilities and staff in all the commercial buildings seen at the right. CEI's main building is in the center of the photo. During one part of the expansion, Ralph Grimm was so concerned about moving sensitive equipment, he paid engineers overtime to wheel and carry things across the parking lots to relocate to a new space. |

|

||||

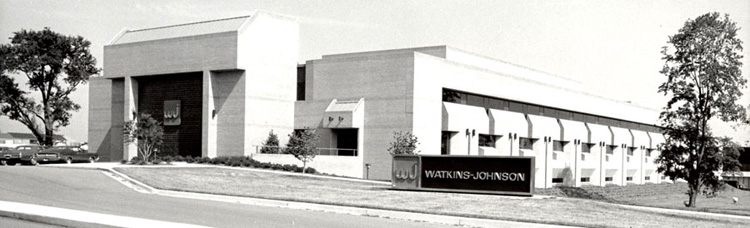

Three years after moving into Executive Blvd, CEI needed to build another new facility. Vince Noonan convinced Ralph Grimm to seek financing by making CEI a publicly traded company. The West Coast microwave firm Watkins Johnson, believed CEI was an ideal acquisition to facilitate expansion into East Coast markets. Watkins Johnson started in Palo Alto, California as a manufacturer of traveling wave tubes. They were expanding steadily based predominately on innovative microwave devices and Air Force missile and space contracts. Thus in 1967, Communication Electronics, Inc. became a division of Watkins Johnson. The CEI logo on the front of the building was removed and replaced with a WJ logo in January 1969. In the negotiations for acquisition, Ralph Grimm retained the title of manager and the old Rockville facilities became the CEI division of WJ. The Rockville facility continued to thrive with operations sprawling into five buildings just before the new Gaithersburg facility was completed. In May, 1973, the CEI division moved from Rockville to 700 Quince Orchard Road in Gaithersburg, Maryland. The three story building was originally vacant on the third floor to allow for expansion. It was primarily an open floor plan manufacturing plant but also housed all the engineering and business offices. |

|||||

|

|||||

The architect designed the new facility to resemble an integrated circuit, a relatively new electronic device at that time. CEI had come along way from building radios with vacuum tubes above a car repair shop in Bethesda. The technology, the location and even the name had changed but the commitment to excellence remained. There are CEI employees who worked in this building through all the changes of ownership until the present managers, DRS Signal Solutions, relocated the operations in the summer of 2014. DRS Signal Solutions is run by DRS Technologies, which is owned by the Italian firm, Finnemeccania. Though most collectors, hobbyists and some employees refer to the products from CEI's Gaithersburg, Rockville and Bethesda plants generically as Watkins Johnson or WJ, Watkins Johnson was a larger company with many divisions. The equipment designed and produced in this and other East Coast facilities is unique and stands apart from the rest of Watkins Johnson. This equipment often played critical supporting roles in national security missions. Like good soldiers, much of this equipment went to the bone yard without divulging secrets. |

|||||